3D printers are a recent addition to manufacturing and have grown in popularity because of how interesting they are. Laser cutters were invented some time ago and are still used today. So, I did some in-depth research into them and thought I’d put together this helpful article to explain the key differences between them.

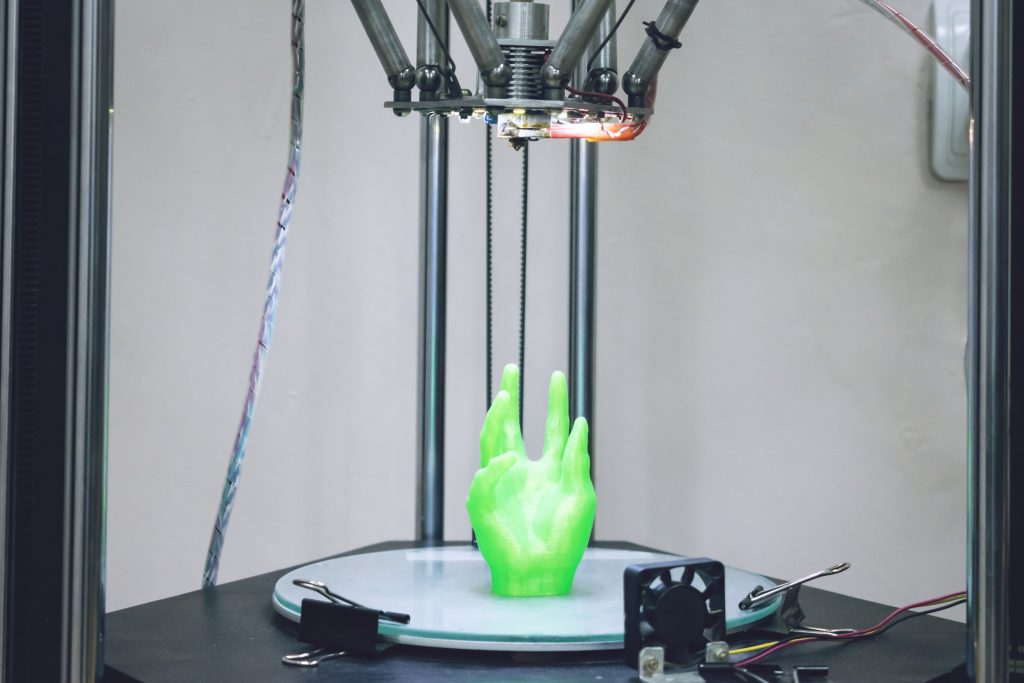

So, 3D printer vs. laser cutter: what’s the difference? A 3D printer creates new objects out of filament that is printed layer by layer. A laser cutter on the other hand cuts pieces out of an existing block of material. The key difference is in how they function, but they can produce similar end products.

Although they produce similar end products, there are key differences in how they work. Also, a laser cutter or 3d printer is preferred depending on what you are using it for. So, below I will explain the differences in what they can make, as well as more details into how to decide which to use.

What is the difference between 3d printing and laser cutting?

The challenge with comparing them is that it is not apples to apples. There are bigger 3d printers and smaller 3d printers. There are bigger laser cutters and there are smaller laser cutters. There are cheap 3d printers, there are cheap laser cutters. There are expensive options as well. So, depending on the technology that you are comparing you might come to a different conclusion. In general, though the differences can be summarised in the following table.

| Laser Cutter | 3d Printer | |

| Speed | fast | slow |

| Fire danger | high | low |

| Accessories and other equipment | Exhaust fan, cooling system | none |

| Flexibility of designs | 2d only | 3d |

| Price | Very expensive | Affordable |

But, I will do my best to level the playing field and just talk about the capabilities of these technologies at a high level, so you can decide which one is better.

So, to begin with, let’s talk about the laser cutters. Laser cutters are faster than 3D printing, no doubt. Of course, individual jobs may vary. You may end up doing a job that has a lot of raster elements in it and therefore it takes a long time to cut. Or, you might be doing some simple cuts and you’ll be done quickly. Doing a straight comparison between the two, a laser cutter definitely wins on speed.

Yes, 3d printing is slow because you are starting from an empty bed, and building things up layer by layer. 3d printing has to work every layer, and high detail parts take even longer.

If you’re only working with mini 3d printers, you might be able to get away with having your prints only taking a little bit of time. But, then you’re only printing little things as well. So, laser cutting for big objects is the clear winner on this one.

The other thing about laser cutting is it is a more mature technology. It has been around for a little bit longer, and people have had more time to work out the kinks and make it work well.

It’s definitely got that going for it. But, for being so mature there aren’t many home options of an affordable nature.

3d printing could make just about anything that a laser cutter can make. Because laser cutters work on flat surfaces. Well, 3d printing can do flat surfaces, but it can also do flat surfaces that stand out, and have parts that are maybe artistic but functional. Parts that stick out from the surface that laser cutting can’t even touch.

Now, of course, every rose has its thorns, and laser cutting is no exception. In fact, in the case of laser cutting you really need to consider ventilation. Laser cutters require a big tube going outside. A big powerful fan trying to draw the air out.

There is also a big cooling system underneath a laser cutter that is necessary to keep the laser cutter at a manageable temperature.

The entire laser cutter is not enclosed at all. It tends to sprawl all over the place, even to do the simplest laser cutting job.

On the other hand, a 3d printer is all self-contained. It doesn’t require anything more than the box it has, and it doesn’t require any external components.

It is neat and easy to put in a home. Though we recommend to keep them in the garage, you can put them anywhere, which is a big plus.

On the design side, laser cutting is a little bit easier. All you have to do is work with 2 dimensions (2d), or flat surface. You might have to learn a little bit of vector cutting. But, other than that drawing with vectors is nothing new to learn, and again, you are only working with 2d.

So, design-wise it might be easier to get started with a laser cutter because you only have to deal with two dimensions. But, it does limit the amount of design you can make.

Now, with laser cutting, you will always have some amount of waste. Every project you are doing, even if you are using the space effectively, will have some portion of waste. With 3d printing, there is a little bit of waste in support materials, and possible wasted prints if you have some sort of printing failure.

Generally speaking, the waste from a 3d printer is a lot less. You will accumulate volumes and volumes of a board that you are keeping around, hoping that one day you will have a piece that is the right size to match what you need. It’s more cumbersome doing 3d printing than a laser cutter.

Now, there is the question of safety. With a laser cutter, you are cutting things with fire. The fire danger is not a question of if, but when, and whether you are prepared for it.

All the systems involved in a laser cutter for keeping it contained are good. But, you cannot under any circumstances leave a laser cutter to run unattended.

You might leave a 3d printer to run unattended, mostly because you have to eat and sleep once in a while. But, generally speaking, it is not going to burn your house down, but with laser cutting, is going to make a valiant effort if you aren’t watching it. That being said, I will explain below what exactly a 3d laser printer is because this can cause some confusion.

What is a 3d laser printer?

A 3d laser printer lets you take a pen and ink drawing, or something you created with Adobe Illustrator or Photoshop and actually print it on wood, fabric, cardboard, even chocolate. It uses a laser about the width of a human hair.

It can cut very precisely which lets you take your design and use and sell it. It can create something beautiful, something useful, something for your family, or something for your business.

Traditional 3d printers are like a robot with a tiny hot glue gun, they build things out of layer upon layer of melted plastic. A laser cutter uses subtractive technology instead of additive. You start by putting in a piece of wood, leather, fabric, or cardboard.

Then the laser cuts and engraves that material to produce the result. What that means, is that the results aren’t made of plastic, they are made out of beautiful natural or man-made materials.

Some applications of this technology have made their way into the medical space, such as laser surgery. Pediatric cardiologists have used technology to replace more expensive equipment. This allowed them to practice a surgery 10 to 20 times rather than once or twice before using it on a real patient.

Although a laser cutter is an older technology than 3d printing it is still innovative technology and there are many planned improvements and new features.

Do 3d printers use lasers?

When people talk about 3d printers they normally mean a fused filament fabrication 3d printer (FFF). It is also commonly referred to as an FDM. This type of 3d printing is the original 3d printer. These don’t use any lasers.

Recently, there have been advancements in 3d printing technology that spawned a new method of 3d printing using resin. This type of method does use layers. It is called stereolithography or SLA for short.

So, how do 3d laser printers work exactly?

It is covered by a light-blocking cover (more on why this is used later), in which there is a build platform housed within the 3d printer. The parts are made on the build platform that hangs upside down and is submerged in a resin tank.

The resin tank has a transparent base which provides a path for the ultraviolet (UV) laser to shine through. When starting to print on a 3d laser printer, a file is uploaded to it and the resin tank is filled with resin.

The laser shoots very rapidly back and forward and hardens the plastic. As this occurs the build platform is raised pulling the hardened plastic out of the resin. When the part is finished it is submerged in rubbing alcohol and washed to remove any remaining resin.

An SLA 3d printer is known for producing extreme detail with layers that are 4x times finer than a human hair. There are also different types of resin. Some are soft and spongy, whereas others can withstand big impacts like being hit with a hammer.

With SLA 3d printing prints come out nice and smooth, whereas with a FFF 3d printer you can see and feel the individual layers of filament.

The individual layers also create a plain of weakness, which causes the print to break between the individual layers much more easily. SLA printing, conversely, creates a chemical bond between the layers and requires much more force to break individual parts.

What can you make with a 3d laser printer?

There are many things you can make with a 3d laser printer, below I will list some of the coolest and most useful things you can make. Most of these you could create a small business out of using an online store, eBay, or Amazon, or just sell them to your friends and family.

Showerheads

You can create custom shower heads in a bunch of cool designs. You can use animal heads such as lions or tigers, or for a dark touch, you can print a skull. You can experiment with interesting shapes that appeal to your favorite hobbies, movies, or tv shows.

Bottle openers

Everyone loves a novelty bottle opener. Whether it’s a Darth Vader head from Star Wars or one with your name printed on it. Perhaps you could print some encouraging words like ‘cheers’.

Planters

You can make interesting designs that sit around your pot plants. Giving them an interesting twist, and you can create designs that match the decor in your home or office. The sky’s the limit with what you can design.

Outlet protectors

Those with small children need these. Stopping unattended little ones from sticking something in them, and getting an electric shock. Why not turn them into something interesting that blends in with the style of your home.

Penholders

There are some pretty creative designs you can come up with for a pen holder, such as the hexagonal shape of a honeycomb, or strands of a person’s hair.

Drink coasters

These print pretty fast because they are flat and thin. You could have a few collections to entertain different types of guests. Keep your State coasters for the relatives, and bring out some interesting ones for other guests.

Wall mounts

You can create wall mounts that you screw into the wall for things like bicycles, musical instruments, and large mirrors. You may not be able to find the right size and shape that you want. In which case, you can make it custom.

Measuring cups

For bakers and chefs alike, the precision of a measuring cup can be printed in your own home. You can customize them with intricate patterns or words.

Chip clips

These are small little items that are useful around the home. Good for that massive bag of corn chips, or to keep pasta and rice airtight.

Tube squeezers for toothpaste

Small and fast to make, these are ideal to 3d print. Making it easier and more convenient when brushing your teeth.

Candleholders

You can make bases with a lampshade type design. When you light the candle inside it makes cool patterns on the wall as the light flickers and shines through your design.

Others

Other interesting things you can make for your home or to sell are:

- vases

- doorstops

- earbud holders

- zipper pull replacements

- drain covers

- smartphone and desk stands

- phone cases

Can you cut and engrave metal with a laser cutter?

Most laser cutters are designed to be used to engrave metal. Laser cutters used for industrial purposes can cut metal. But, these are generally larger and more expensive than what you have in your own home. As previously mentioned laser cutters need additional attachments such as air extractors and cooling systems.

Consumer-grade laser cutters which cost around US$1000+, and can be used to cut or engrave:

- Leather

- Paper

- Glass

- Stone

- Rubber

- Felt

- Cotton

- Denim

- Plywood

- Walnut

- Oak

- Maple

According to Digilab. Some types of metal are more easily engraved whereas others are far too strong to be cut with a laser. You can engrave the following metals with most laser cutters:

- Aluminum and aluminum alloys

- Brass

- Copper

- Mild or carbon steel

- Stainless steel

- Other types of steel, such as corten or galvanized steel

There are specific issues you can run into when engraving metals and each metal has its own foibles. For example, Aluminium is highly reflective, which acts like a mirror when being cut with a laser cutter. You should look through the user manual for your specific laser cutter, and information about how to engrave or cut the specific metal you are using.

Again, this will rarely be done in the home for most hobbyists, because of the complexity and safety issues.

What is the difference between a fiber laser cutter and a CO2 laser cutter?

There are two main types of laser cutters that are in use today, fiber laser cutters and CO2 laser cutters.

CO2 laser cutters

These types of laser cutters can be used on a range of materials in addition to metal such as textiles, plastics, wood, acrylic, glass and stone. CO2 lasers relative to fiber laser cutters are faster and cut through the material faster.

This is because of their larger and less precise beam. The larger laser beam they emit can suck significantly more power. But, doing a cost calculation it can be more economical to use a CO2 laser cutter than going with a more expensive fiber laser cutter.

Fiber laser cutters

Fiber lasers have a precision of up to 100 times that of a CO2 laser cutter. As a result, they are suited to annealing, engraving, and etching.

They are particularly useful in high detail and high precision applications such as barcodes, serial numbers, and circuitry. Though you probably won’t use one in your own home, it is important to know the difference so that you can make an informed decision.

Fiber laser cutters go a long time without needing to be serviced and use significantly less power than CO2 lasers.

How much is a laser cutter?

There are two types of laser cutters, fiber laser cutters, and CO2 laser cutters.

Fiber laser cutters are more expensive than CO2 laser cutters. Laser cutters are typically made for your specific requirements. The factors that influence how expensive or cheap a laser cutter is are the wattage, and work-surface, according to Business.com.

An average price is USD$2,000 to USD$5,000 for a CO2 laser cutter.

Fiber laser cutters run about USD$40,000 to USD$1,000,000.

Can a laser cut fabric?

A laser cutter can cut wood, cardboard, and fabric. You will be risking creating a fire inside the laser cutter as with other materials. This is because the laser cutter uses extreme heat to burn through the material. There are some fabrics that are less prone to fire risk than others. So, below I will discuss the different textile fabrics and their risk of fire.

- Cotton and linen. On their own, these are moderately flammable. Typically, flame retardant chemicals are added to inhibit combustion.

- Acetate and triacetate. These are less flammable than cotton or linen. Similarly, flame retardant chemicals are added to stop them from catching a lite.

- Nylon, and polyester. These fabrics are difficult to ignite, but when they are on fire, the material melts and drips. This can burn you if it gets on your skin.

- Wool. A natural fiber, it is harder to catch fire when being burned or exposed to an open flame. It burns very slowly, and self extinguishes.

- Modacrylic and glass fibers. These are synthetic fabrics made from chemical compounds called polymers. You may have run into these fabrics if you accidentally ironed a shirt too hot, and left shiny marks on your clothing, especially around the collars and seams. According to Wikipedia, they are flame-retardant and don’t catch fire. If they do catch fire, they will self-extinguish similar to wool.

| Textile | Ease of catching fire | Rating for using laser cutting on it |

| Cotton and linen | Medium | Average |

| Acetate and triacetate | Low | Above average |

| Nylon and polyester | Low | Average |

| Wool | Very low | Above average to very good |

| Modacrylic and glass fibers | Very low | Very good |

Felt and fleece fabrics can be laser engraved and laser marked. This can make for some cool designs you could try out with a laser cutter.

Related questions

Can cardboard be laser cut?

Cardboard can be laser cut using a CO2 or fiber laser cutter. Laser cutters can cut through stone, metal, plastic and other hard materials. Laser cutters use intense heat to burn through the material. Because cardboard is so thin and light a laser cutter makes short work of any cuts you are doing.

Laser cut cardboard is a common product you can buy from specialist manufacturers. These machines are fairly expensive costing over USD$2000.00. So, most people don’t use them at home, and they are primarily used for commercial and industrial purposes.

Are laser cutters dangerous?

Laser cutters pose a significant risk of fire, and they can’t be left unattended. When making cuts the material is housed inside of a protective screen that won’t function unless it is locked. That limits the cause of accidental injury. Personal protective equipment (PPE) is required to be worn when using a laser cutter at commercial sites and Universities where they are used.

A sample document for safe use of a laser cutter can be found at this link. It shows the safety guidelines for using the laser cutter at Yale University. This gives you a rough idea about what to watch out for.

You should look through the operating manual of the specific laser cutter you are using to ensure you are operating it safely, and if in doubt you should contact the manufacturer.

As with all items sold to consumers, they are subject to the requirements of the Federal Trade Commission (FTC), so that they meet minimum standards of safety when sold.

What is the difference between laser and plasma cutting?

Laser cutting uses very high heat to melt or burn the material. Plasma cutting on the other hand uses various gases to make cuts.

The gases are stripped of ions using an electric charge so that when they hit the material they cause a chemical reaction to strip away the material. The gas is also blown at high speed which blows away the dislodged material.

Plasma cutters are used in large scale industrial production, as well as, in small hobbyist type stores. [optional: if you are interested in whether you should use a laser or a plasma cutter check out this article we wrote by clicking [here]]

Conclusion

3D printers are primarily used for making items from scratch, whereas laser cutters are used to cut out shapes and engraving. Depending on the requirements of your project or business you can decide which one is best for what you want it to do. 3d printers on the other hand, that include 3d laser printers are used commercially and can be used in your home. However, laser cutters are too cumbersome and expensive for an average person to want in their home.