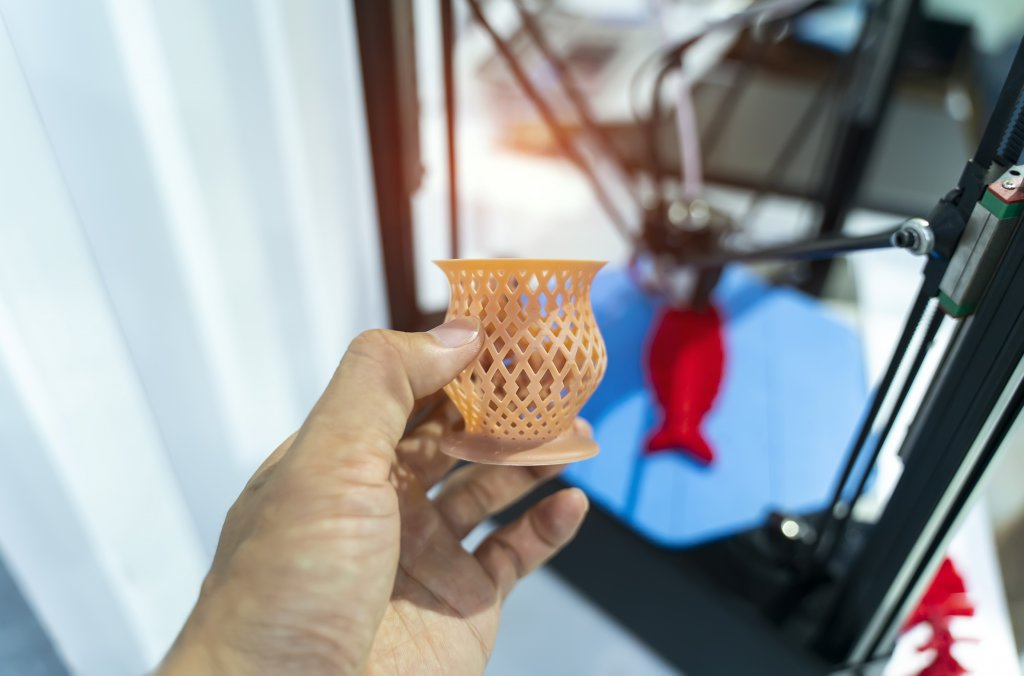

When you finally have your 3D printer up and running it may seem odd that the first print you do is not perfect. Then as you try to print more and more you’ll notice new and odder mistakes; this is all normal for the first time you are printing and there are solutions. Many people notice quickly that their 3D prints are usually doing better at the start but quickly deteriorate as the machine is used more.

To get the perfect 3D prints almost every single time you will need to check the nozzle, align everything, and add a heated printing plate. Further, doing post-processing, cleaning the printer, or using different filament is an easy way to greatly increase the quality of your 3D prints. Checking on the extrusion speed, nozzle temperature, and filament condition can also greatly increase the quality of prints.

There are many things you can do to create masterpieces of 3D prints with many of them not always being the easiest to implement. Many people around the world have learned what works with their printers, while many more are constantly adjusting to find new ways to print better. These are the most basic ways to increase the quality of your prints, and the reasons why they may be needed.

What are the reasons a 3D print won’t look good?

While finding the best fixes to get the best prints are easy, you can find many ways even in the manual of your printer, understanding why these fixes are needed will be vital to preventing things from going wrong. You can certainly make a mistake and have the print be entirely wrong for what you need, while it is much more likely that the printer just needs a bit of maintenance.

These are usually caused by either bad sliver programming or simply wear and tear over age. The more you are printing the more likely you are to experience some of these issues, fortunately, they are easy to spot and once your eyes are trained you’ll be able to spot them within seconds.

- Bad Adhesion: The most common problem that you will find with faulty or bad quality prints is the adhesion of the printing surface. This can cause low-quality layering, moving parts, gaps between layers, skewed prints, and even nozzle clogging.

- Over Extrusion: Something that happens right after you are using a new type of filament is the extrusion needs to be adjusted. If you are using the same nozzle and filament that you started with it may not be needed, however more often than not, you’ll see filament all over the place because too much is being pushed out. Meaning the nozzle cannot melt the filament fast enough.

- Under Extrusion: Overcorrecting is usually what causes the setting to be too slow when the extrusion is too many things that can happen to your print. First, the nozzle will be moving too fast for the filament, leaving gaps in the prints, while the filament can be too hot and will quickly cause leaning one way or the other. Layers will be rougher and previous layers may even be melted by the filament that got heated too much.

- Knotted Filament: When the printer is busy printing it will constantly be pulling on the giant spool of filament you connected to it. However, this could introduce a weak point if you started the feeding improperly. Most likely to happen is the filament gets knotted on the wheel, which can be recognized by the filament going underneath itself. The printer may just stop printing with most modern printers throwing errors, but your print will already be damaged and unevenly printed.

- Unlevelled Bed: By far the most common problem faced by anyone is a printing bed that is not level. This means that it is leaning to one side or the other, which is how many 3D models become leaning towers or simply have weird bubbles in them. Unlevelled beads are caused by anything from uneven tables to accidental bumps made to the printer.

What are the 10 basic ways to improve the quality of a 3D print?

Now that we know what can cause bad prints we need to look at all the easy ways to fix bad 3D prints. Most of the fixes that apply to bad quality 3D print can be done in a few minutes and will become so ingrained in you that you won’t even think of them.

However, if you’re a first-time printer or using a brand-new 3D printer it can be confusing to figure out what is wrong. Some of the most frustrating moments for any 3D printing master is when something goes wrong and all the usual fixes just aren’t working.

- Right Filament: Not all 3D printers are meant for all filaments, with lower quality printers usually not being able to print harder filaments. You should be able to see the rating of the printer and how hot the nozzle can go, which should affect the filaments you are trying out. Matterhackers has easier guides that you can use on their 3D printers, which are the most popular printers for hobbyists.

- Set Nozzle Height: Usually people only do this at the moment they replace the nozzle, however, it is important to remember that the nozzle will wear down with time. Ensuring that the 3D printer knows where the nozzle is exactly, will ensure the settings you are using between layers are perfect.

- Nozzle Temperature: A typical mistake that some make is not adjusting the nozzle temperature properly for each type of filament. Each type of filament needs a different temperature, each thickness needs a higher or lower temperature and in some materials, even the color can affect the temperature. There are guides for each type and thickness provided by manufacturers to get the best print.

- Maintenance: Maintenance on a 3D printer can take a while but if it is not done then your prints will start to lose quality fast. Printer nozzles need to be replaced, things need to be aligned and sometimes the printer just needs a few key internal things adjusted. Motors get old, wheels wear out, and belts can break with age.

- Filament Care: Filament care is not specifically the filament you have on your 3D printer at the moment. Most people will buy one or two extra rolls of filament once they found some they like. Enthusiasts will have an entire wall of filament ready for them to use, and this is where the care is needed. 3D printer filament is hygroscopic and can also be brittle, stopping any moisture from being absorbed by the filament and all hard knocks will save you many headaches down the line.

- Adjust Printing Speed: The printing speed is driven by two things, how fast the nozzle moves while printing and the speed at which the filament is pushed through. If you are seeing mistakes, missed areas, or streaks, you will need to change the speed of these two. One can drastically affect the other and having them perfectly balanced is an easy way to have a perfect 3D print.

- Different Build Plates: 3D printers all have beds, and these beds all have plates on them. Depending on the size of your print, the heat from the bead, and the quality of your filament a different surface can go a long way. Some plates are rough and textured while others are smooth and soft, some rare prints even use the plate as a sacrifice, having it be a part of the complete print once done.

- Different Slicers: Slicers are what printers use to make their models more manageable and getting the right one for you can be a challenge. However, it is advised that you try a few different ones before settling, as most of them are free and offer different functionalities. Once you have one you like it is a good idea to play around with it until you learn all the features and tricks that you can accomplish with it.

- Post Processing: Something that many young 3D printing lovers forget when they get their first rough print is the need to do the post-processing. It is vital to remember that all 3D prints will need some work once they are out of the printer and doing it properly can greatly increase the look of your prints. Just be sure you don’t sand away any fine details you added into your print.

- Clean Printer: There are two things you will need to constantly clean to ensure good prints from your 3D printer, the nozzle, and the bed. The bed of your 3D printer should ideally have no dust or previous prints on them while the nozzle needs to be cleared from any dry filament sticking out of it. Doing this will mean your prints start good and there is no place to go from there but up.

Why are there some prints that need more than just the basic ways?

Everyone hopes to have an easy fix for the faults in their 3D prints, with most people being entirely successful at fixing all the mistakes they see with just a few added things. However, some things need a more in-depth look, that will require a bit of money to be spent beyond that of a few dollars.

These are for 3D printers that currently do no have heated beds, nozzle technology that is not good enough or even just adding complete systems on top of the printer already. Prints that have are not straight, have holes in them, or simply are not printing at all. To fix parts of the printer that is not good enough or simply damaged is not something that can be done within a few minutes.

It is vital to remember that 3D printers are still machines and that they won’t work perfectly forever. Some of the best printers in the world need more maintenance than just hobbyist printers, usually because there are more complex parts at play. It is vital to remember that some of the easy fixes are only fixed to solve something temporarily.

What are the complicated and expensive ways of improving the quality of your 3D prints?

A quick fix can improve the quality of a print that is already almost good, most of the time helping you to find the error in the programming or design that you made. There are many ways to quickly fix something that can save you money, however, there are important changes that you should consider that may be a bit more expensive.

These are the things that people do when they learn that their printer is not quite capable of doing everything they want to do. Most printers can be upgraded and improved until they do everything you need them to do, these are the first steps to getting your printer on the road to being capable of doing it all.

- Install Heated Bed: Most 3D printers out there today will have heated beds, however, some of the more budget options won’t. Adding a heated bed is a quick and easy way to drastically increase the quality of the prints you are doing, but it will cost a few hundred dollars to get one that perfectly works with your 3D printer.

- Enclose Printer: An enclosed 3D printer may seem like something that is meant for someone who wants something to look at, but this is not the case. Enclosed printers serve several things, chief of which is protection from winds and temperature drops. As most printers take a while to print the layers can be too cold if there is a draft, or worse, sand, and other contaminants can appear that cause problems while printing.

- New Nozzle: Most hobby printers are capable of easily go the whole life of their printer without having to buy anything fancier than a brass nozzle. However, when you are finding your prints are constantly bad, and that you are replacing nozzles what feels like every week you should look into getting more expensive high wear nozzles that can handle the punishment of constant prints.

- Adhesive Printing: If you don’t want to get a heated bed, or the area you are working with is too large to get an affordable heated bed there is an alternative. It can be complicated by many people use glued or sticky surfaces to print on, usually spraying on some glue right before printing. This allows the print to easily have something to adhere to without being moved all over the printing bed.

- Specialized Beds: We touched on this earlier, but most people won’t be using just a printing bed anymore, instead of relying on plates that are stuck on top of the bed. These are usually made by BuildTak and can be stuck directly onto the bed or in combination with a FlexPlate system be magnetically attached. These can provide surfaces made from any material and will usually be either perfectly smooth or slightly rougher than a normal bed. They also save the bed from damage, creating a long use life for your heated bed.

- Learn Your Slicer: The slicer that you are using may be the one included with the programs for the 3D printer or it could be something much more complex. Depending on what you are using it can drastically change the quality of your prints. It may take some time and patience, but learning all the ins and outs of your slicer could mean your prints are no longer just being done. They could be completed with minimal requirements for excessive cutting or support.

- Advanced Post Processing: There are many ways of post-processing any 3D print and each of them will be unique to the shape and size of your print. However, above sanding there is heating, polishing, or chemically processing the print that will make it look so much more amazing. These can be more expensive and time heavy than simply sanding away the rough edges and be chemically dangerous to do if you are unsure of the processes.

Why are first time printers likely to make a mistake?

Before you go out and buy all the latest and greatest in 3D printing technology it might help to take a look at what you are currently doing. So many first-time creators go out to try and get the latest piece of technology or aide because they are unsure about what is the problem with their prints.

Simply put if it is the first time you are printing something or you are printing the first time for something that you designed, then you will most likely have made mistakes. This is why your first print will usually be a flop as you are not always aware of the things you need to check. Some of the most common faults are when the slicer has been programmed wrong and the wrong type of filament is used.

However, it may be that there is something more complicated wrong with the print, however, understanding when to look for this is important. Many owners prefer to test with different feeds and temps before going and replacing parts of their printers. This allows them to see exactly what they may need to add and how that will benefit them.

What can be used to make post-processing more effective?

Having the perfect print is amazing, but few prints are perfect when they emerge from the printer, this is because the prints will be layered. Everyone that has ever had to work with fine detailed 3D prints will know that some refinement after the print is required. To do this there are several ways, with each type of filament working better with certain types.

You may know that several cosplayers specifically use some filaments for the ease at which they can be processed. Sometimes creating something that looks significantly better than just something they could have made by hand or bought at the store. It is important to remember which processing works the best and will be able to give the most accurate surface detailing’s.

Sanding Grits

The best and easiest post-processing that any piece of 3D printing can receive is good sanding, with either files or sanding paper. If you are working towards getting something that is entirely smooth it may be best to print a bit thicker than planned, which will allow for more grits of sandpaper to be used.

This is vital as you can get near-perfect finished with only sandpaper, especially on harder filaments that can be sanded into mirror surfaces using nothing but a piece of sandpaper and some water. Many owners of 3D printers will have walls of sandpaper next to their walls of filament rolls. Sandpaper is the best friend for any 3D printer owners.

Solvents on PLA

A trickier thing to get perfect is the solvents you can use to smoothen prints, this is usually done on PLA filaments, owing to its reactionary state with common solvents. If you are wondering this is usually acetone or nail polish that will be used. Sometimes it is preferred to dip larger parts, however, this is dangerous as it can melt more than you want.

The best and recommended way to use PLA to smoothen your prints is by having the vapors do everything for you. Using a glass bowl have the print suspended in the middle and then have the acetone poured in at the bottom. Timing it perfectly as leaving it too long can entirely melt your 3D print, making it nothing more than a toxic pool in the bowl.

Applying Heat

A much safer but tricker way to get almost glassy finishing on your print is using a heat gun, this will melt most of the common filaments that you can use on your 3D printer. Giving a look that is remarkably similar to that of solvent, with the added caveat that you can have more directed control over everything and how they would be melting.

However, melting can introduce several structural defects, and many times you may see parts that are drooping that you would never want to have drooped. This is because the parts will not be expecting to be melted again, with heavier un-melted top parts no longer having the hard support they need. You should always be careful about which parts you are melting as smaller parts tend to be damaged more than anything.

Polish with Polish

This is one of two post-processing techniques that require you to do sanding before you start, but it can deliver some of the best results. If you are happy with the print as is then you should be sanding it down to make it smooth, however, if you want a true mirror finish then polishing it is the way to go.

This can be tricky with complicated shapes, but smoother shapes can easily be polished using the right polishing compounds. Polish is the finest form of sanding that you can get, which is why you will see most people sanding something smooth before they start polishing it. Just be sure you are ready for the work, it can take a bit longer to get the perfect polish, even on plastic.

Painting the parts

The most common thing that you will see in the cosplay world is simply painting the printed parts, not only is this easier, but it allows for more customization which is something many artists require. Painting can be done with special paints and care should be taken that the pain does not contain any solvents at all.

For the best results, and the smoothest, a layer of primers should be applied that allows the next layers of paints to easily adhere to the piece. This will soften many edges and make the print look a lot more complete than it normally would.

Conclusion

Your trip down the road of perfect 3D prints will be a tough one and many times you will hit your head against what you think is a wall. Understanding what to look for and identifying mistakes that you have made is the best way to start creating some of the best prints your printer possibly could.

Just be sure that the printer is ready and heated, many a tear has been shed because the printing bed was not switched on at all!